Grind the beans, don't crush them

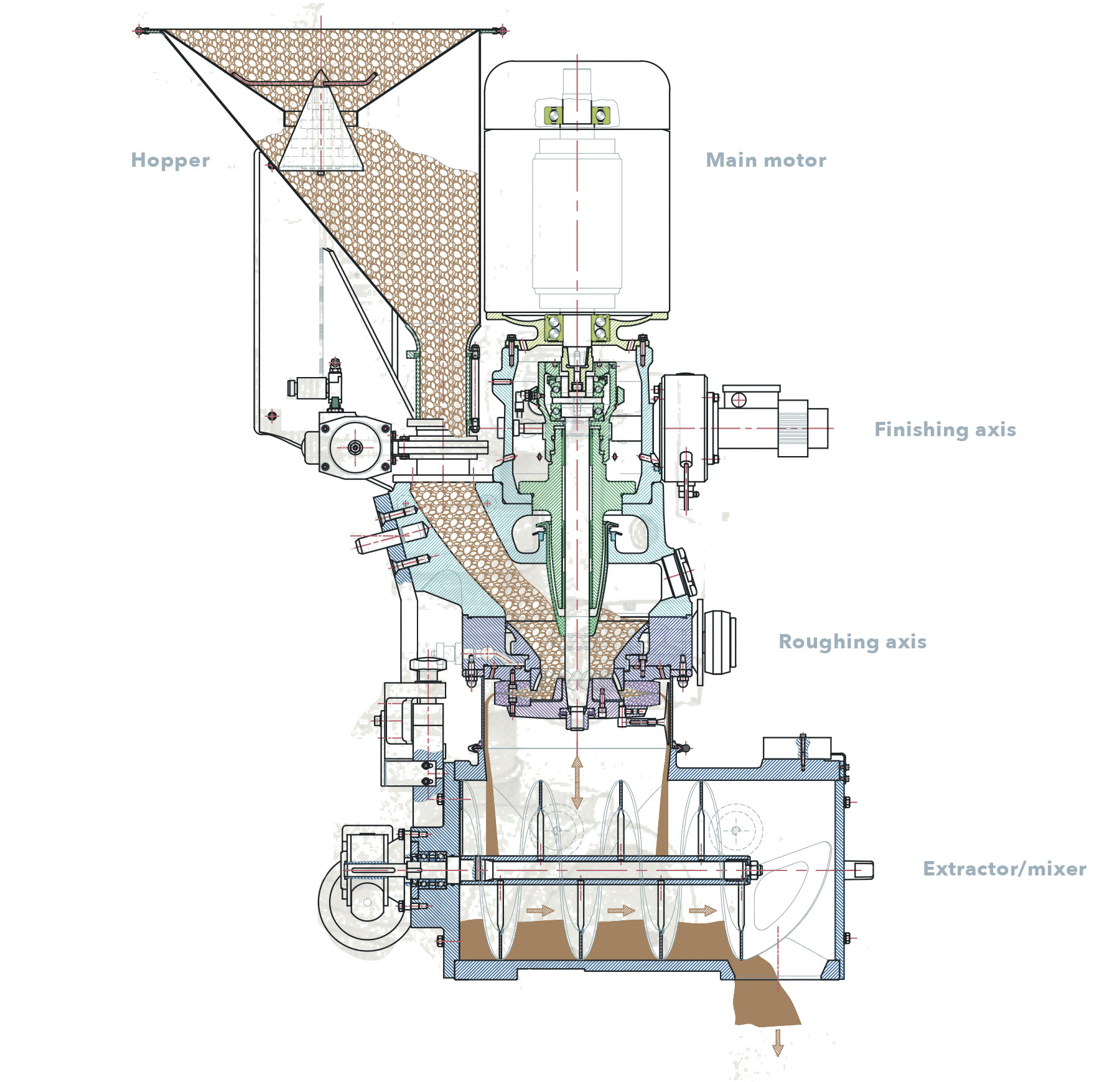

The Colombini factory have been making the world’s leading grinders for seven decades. In a Colombini grinder precision engineered tungsten discs cut the beans, instead of crushing them. Think of it like using a scalpel instead of a hammer. This preserves all the microcells within the bean, and lets the ground coffee retain all flavours and aromas. Just as importantly, the disc system grinds the beans without compression. This minimizes heat production in the grinding process, keeping all the original flavours intact.

Micrometric consistency

Colombini grinders have been designed with the express purpose of being easy to use, simple to manage and long-lasting: the result is machines with extremely precise adjustment, even after years of work under all conditions. Grinding adjustment, truly micrometric and consistent over time, has been one of the features that have determined the particular success of the TA series in the production of single dose coffee.

Thanks to the mechanical characteristics and the design of the “cutting discs” the Colombini grinding system is extremely efficient in terms of energy: a grinder in the Criomak series guarantees an hourly capacity of 900 Kg/h of espresso product, with a consumption of just 6-7 kW/h.

Versatile reliability

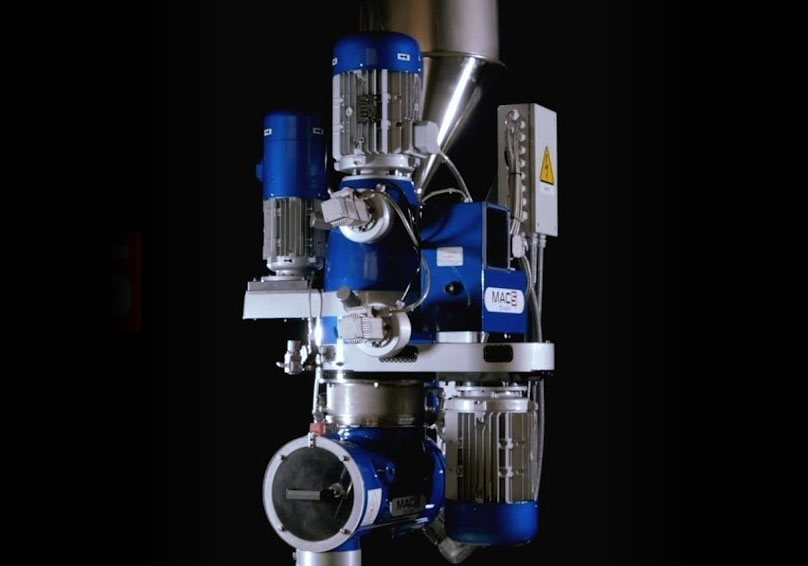

Because of the dimensions and extremely low weight in relation to the production capacity plus the possibility of obtaining even very diverse granulometries with the same machining unit, Colombini grinding units have a host of different applications; from directly feeding single dose packaging machines to direct positioning on silos for storing the grind etc.

Colombini grinders require no cooling systems, this factor combined with the possibility of feeding packaging machines and storage silos directly, with the consequent elimination of transfer systems for the ground product, makes our system economically advantageous. The running costs are the lowest on the market: the only periodic maintenance is sharpening the cutting discs. Easy access to the grinders and to all their component parts means that maintenance, cleaning and tool changing are simple, fast and easily managed by the user’s own company.